Rodents have remained one of the greatest threats to cable infrastructure for years. Rats, mice, and even squirrels can cause significant damage by chewing through both copper and fiber optic cables. This leads to costly outages, downtime, and service disruption. Examples of such incidents can be found all over the world – from New York, through Tallinn, to cities in Poland.

It’s no surprise, then, that sensitive locations such as food processing facilities, critical infrastructure, landfills, or urban telecom networks are increasingly relying on so-called rodent-resistant cables. But what does that actually mean?

Glass yarn in a cable - is that enough?

There’s a common belief that the presence of glass yarn in a cable makes it rodent-resistant. Not quite. In reality, glass yarn is used as a dielectric reinforcement in the cable. It enhances mechanical strength and acts as a barrier against rodent teeth. It works through physical discomfort: the brittle microfibers break and pierce the animal’s mouth or gums, causing irritation and pain, which discourages further chewing.

This solution can be effective, especially where rodent presence is occasional or moderate. Cables with glass yarn are commonly used in buildings, cable ducts, or municipal telecom channels.

Standards vs. reality

The International Telecommunication Union (ITU-T), specifically the L-series recommendations, already indicated over 20 years ago that effective protection against rodents could be provided by both metallic and non-metallic barriers, such as rods or glass yarn. However, that is just one level of protection.

Let’s remember: G-series transmission standards (e.g., G.652.D) concern the parameters of the optical fiber itself, not the construction of the entire cable. Therefore, rodent resistance is determined not by the fiber type but by the overall cable design.

Two levels of rodent protection

In practice, there are two levels of protection:

Basic resistance (rodent-resistant)

A cable protected against accidental or moderate gnawing, usually through the addition of a glass or aramid yarn layer. This is generally sufficient for most environments where rodents may, but do not necessarily, appear.Full protection (rodent-proof)

In high-risk areas – such as tunnels, transformer stations, industrial facilities, or regions with a large pest population – cables with metallic armor are used. A steel tape (CST) or wire armor creates a barrier that rodents cannot chew through. This solution is durable but heavier and less flexible.

Or maybe a hybrid solution?

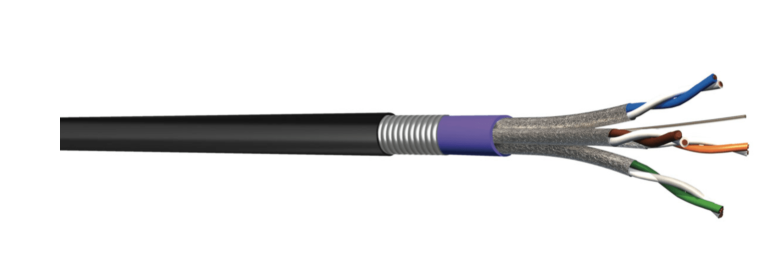

Hybrid constructions are increasingly common: a dielectric cable with glass yarn and an additional metal shield, e.g., under a dual jacket (PE + LSZH). This kind of cable offers strong protection against rodents and mechanical damage, while also meeting indoor installation requirements.

MMC Cables – examples from the portfolio

The MMC product range includes:

MMC 5254ARPE – a category 6A twisted pair cable with steel tape and a PE jacket. Resistant to gnawing and mechanical damage, compliant with 10G transmission standards over 100 meters.

U-DQ(ZN)BH fiber optic cables – featuring glass yarn under an LSZH jacket, resistant to moderate rodent attacks, ideal for building interiors and telecom ducts.

Is glass yarn enough?

Sometimes, yes. But not always. If you’re installing cable in a location where rats are almost daily visitors, it’s better to opt for more robust protection – ideally, steel armor. Choosing the right cable type should take into account not only transmission parameters but also environmental risk. And as we know, that risk can come with very sharp teeth.